10 million pairs! Huashu High Tech's shoe mold additive solution has achieved a comprehensive breakthrough, producing over ten million pairs of finished shoes in mass production

As a typical labor-intensive industry, the traditional shoe mold manufacturing industry is facing multiple challenges such as tedious and complex processes, fragmented labor, strict environmental requirements, and product innovation iterations that better meet market demand. The emergence of new processes and technologies is bound to drive the upgrading and development of the entire industry. 3D printing, as a representative intelligent manufacturing process for the upgrading of footwear manufacturing, will inject unlimited vitality into the research and development of new products and the market.

Huashu High tech, a leading enterprise in industrial grade 3D printing, has been conducting in-depth market research with partners in the shoe mold industry since 2019, attaching great importance to and understanding the supply chain needs of international brands. It continues to innovate in the shoe mold industry and has launched exclusive solutions covering equipment, materials, processes, and software. These solutions have been successfully applied to various products such as popcorn shoe molds, EVA shoe molds, and RB shoe molds. The 3D printed shoe molds have achieved mass production of over 10 million pairs of finished shoes, with industrial customers covering the southern China region and Southeast Asia overseas. They have effectively improved the pain points of environmental pollution, high labor costs, long processes, and low yield rates in the traditional shoe mold manufacturing process, and helped shoe mold customers and brands create environmentally friendly enterprises. Accelerate digital innovation and achieve sustainable growth.

Typical cases of diversified and innovative applications

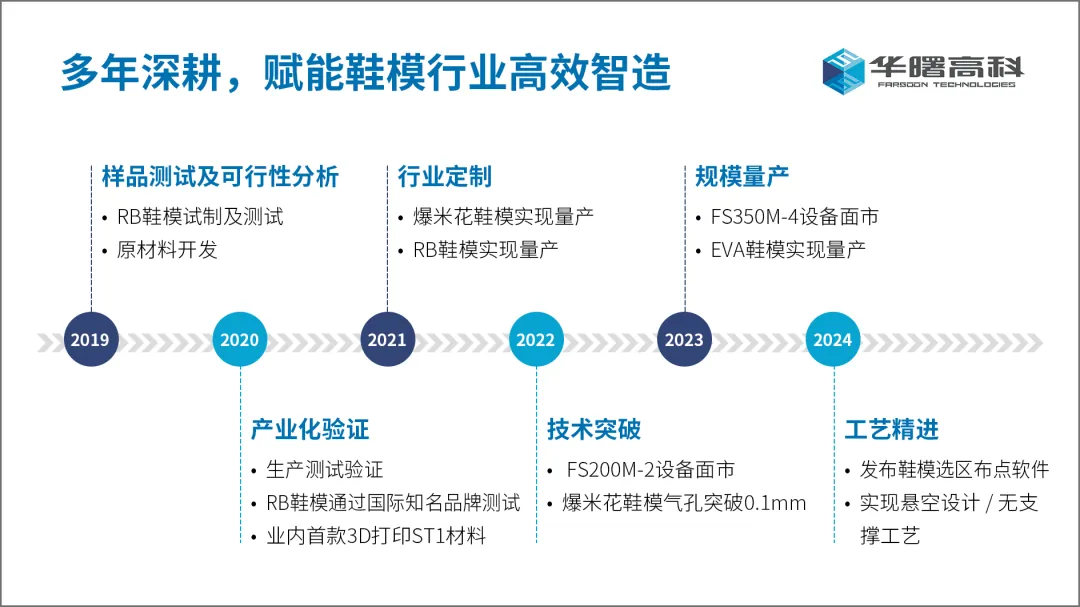

Traditional shoe mold production requires CNC wood mold replacement, wood mold modification, silicone mold flipping, gypsum mold flipping, gypsum sintering, casting metal mold, bite pattern and other processes. The overall process is cumbersome and cumbersome, and it is impossible to complete the fine bite pattern production of some special shoe molds.

Through metal 3D printing, the overall production cycle of shoe molds is shortened, and digital bite pattern technology can achieve a high degree of precision texture restoration of shoe molds, simplifying the production process to the greatest extent possible, improving production efficiency and product update iteration speed, helping shoe mold enterprises achieve efficient production, reduce manufacturing costs, and enhance product functionality and performance.

Since 2019, Huashu High tech Metal 3D Printing Technology has been mainly applied to various products such as popcorn shoe molds, EVA shoe molds, and RB shoe molds. It has innovatively developed more than ten processes, combining traditional shoe mold manufacturing experience with advanced 3D printing technology advantages to help footwear users maintain their advantages in the fiercely competitive market and achieve sustainable growth and development——

Huashu High tech Shoe Mold Industry Industrialization Partner: Guangdong Zhansheng Digital Mold Technology Co., Ltd. is a pioneer enterprise in the industrialization of shoe mold digitization and intelligent manufacturing upgrading through 3D printing technology. It is equipped with more than 30 Huashu High tech metal additive manufacturing equipment FS350M and FS200M, and has achieved large-scale production of metal 3D printed shoe molds.

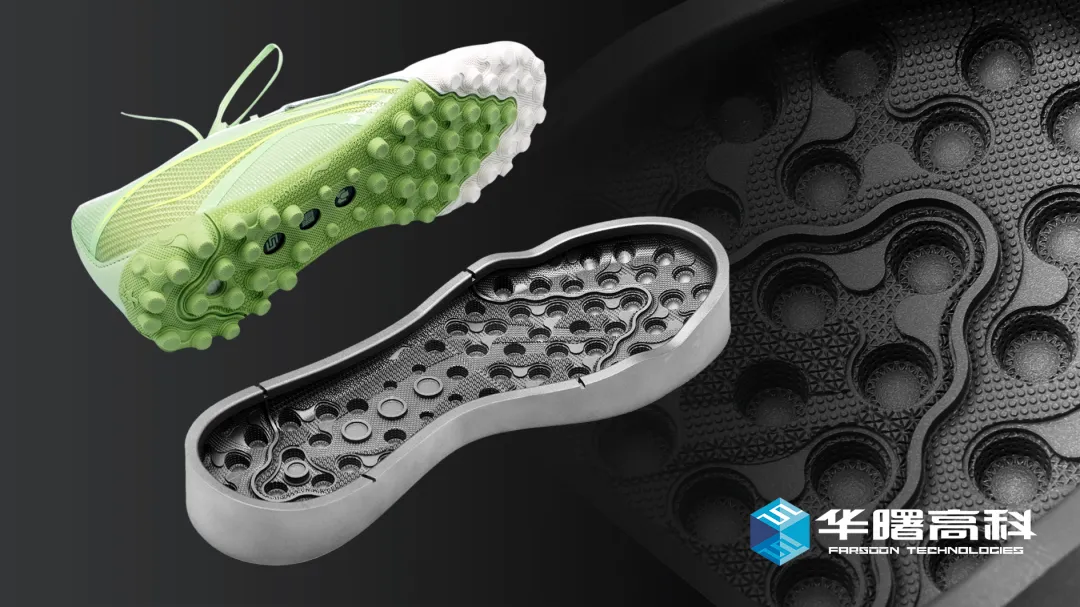

Typical Case 1: Popcorn Shoe Model

Popcorn shoe molds are a typical innovative case of 3D printing technology applied to the traditional shoe mold industry. Huashu Metal 3D Printing has significantly improved the precision of shoe sole molds, with 16000 single-mode air holes and hole diameters exceeding 0.1mm in popcorn shoe molds. This not only achieves excellent breathability but also avoids structural hole blockage, ensuring the lightweight and high elasticity of finished shoes.

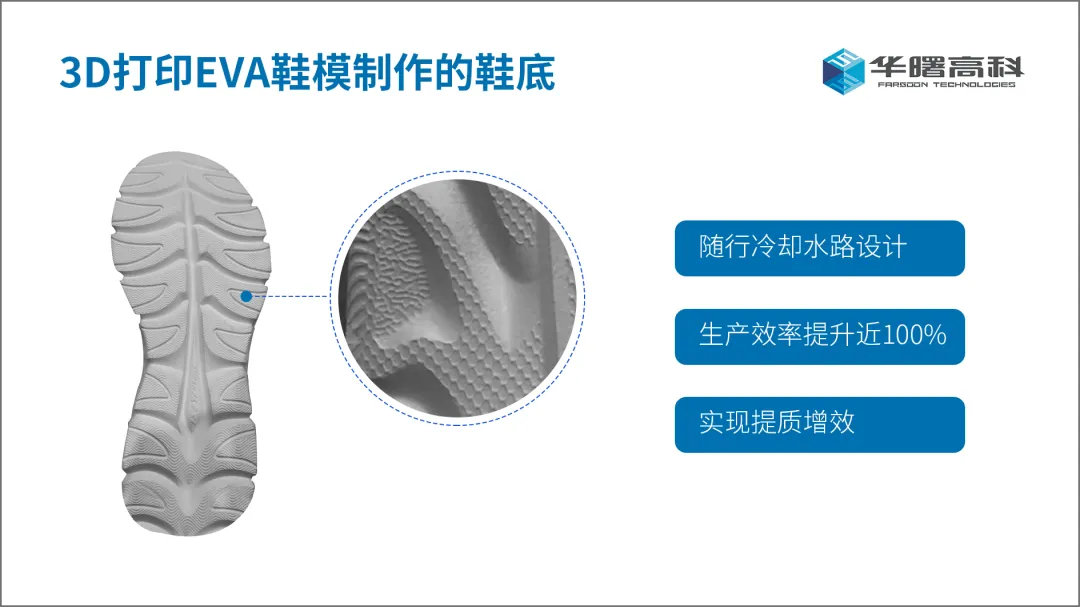

Typical Case 2: EVA Shoe Model

Applying metal 3D printing technology to EVA shoe molds is another innovative breakthrough in the shoe mold industry chain. The traditional production process of EVA foam shoe molds usually requires hot pressing and cooling shaping, and production efficiency often depends on the cooling time. The 3D printed EVA waterway shoe mold integrates a flexible waterway to achieve a tight fit between the waterway and the mold surface, increasing production efficiency by nearly 100% and achieving the goal of improving quality and efficiency.

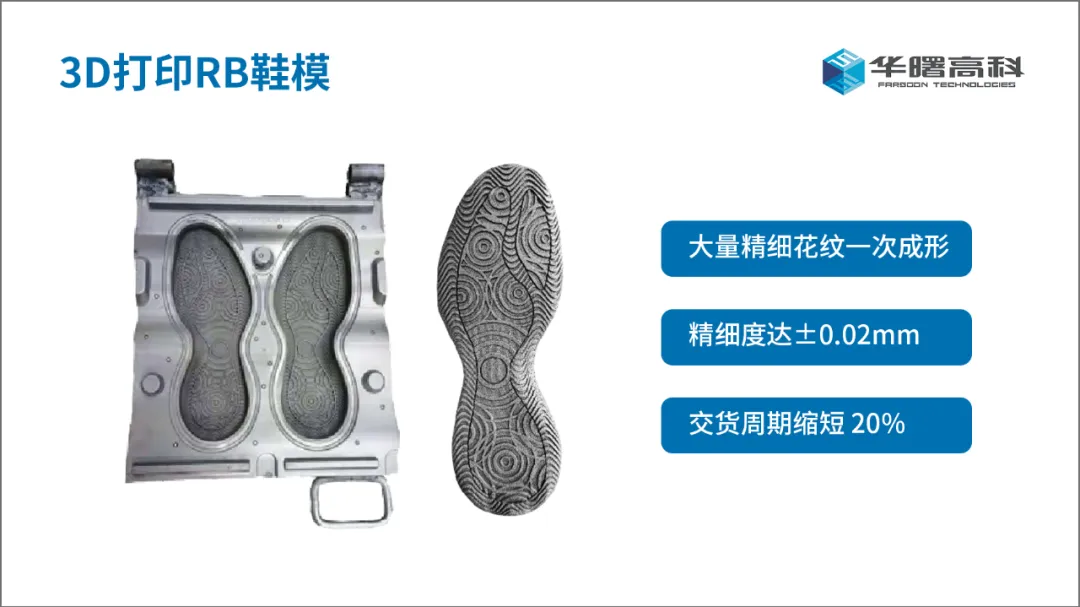

Typical Case Three: RB Shoe Model

Applying 3D printing technology to the traditional RB shoe mold can realize the integrated forming of hundreds of patterns with a precision of ± 0.02mm. Various patterns can be realized on the same mold. Compared with the traditional processing and delivery time, the mold durability is improved by 20%, and the appearance design is more free.

Equipment industry solutions empower intelligent manufacturing of shoe molds

Huashu High tech adheres to the core concept of open innovation, listens to the voices of the market and customers, deeply understands the needs of shoe mold application scenarios, and has launched a variety of metal additive manufacturing equipment that is highly compatible with the shoe mold industry, providing industrialized users with "cost reduction, quality improvement, and efficiency enhancement" batch production solutions.

Taking the FS350M series as an example, it is not only suitable for industrial applications in industries such as aerospace, automotive, medical, and mold manufacturing, but also has significant efficiency and production capacity advantages in the shoe mold industry. The forming cylinder of this equipment has been specially designed with a size of 433 × 358 × 400mm (including the thickness of the forming substrate), which can print one pair of shoe molds at a time, covering 99% of shoe mold sizes on the market; Equipped with 4 standard lasers, the scanning speed can reach up to 10m/s, and stable and mature bidirectional powder spreading technology is adopted; High inflation efficiency, only takes 11 minutes, and the gas consumption during processing is only 3-5 L/min, far below the industry average; Multi layer wind field design ensures uniformity of the wind field and excellent printing quality.

Material development specific material parameter package

In 2021, in response to the special material needs of the shoe mold industry, Huashu High tech and its partners worked together to break through key core technologies such as material burning, composition, and morphology control, and developed the industry's first 3D printable ST1 material for customers. ST1 is a low-carbon alloy steel that can corrode patterns, electroplating, welding, etc. It is commonly used in the shoe mold industry for biting and repairing.

At present, Huashu High tech has developed a series of commonly used material parameter packages for shoe molds, such as stainless steel and aluminum alloy, and solved the problems of high hardness and insufficient bite depth of alloy materials, ensuring the durability and stability of shoe molds.

Combining process efficiency and precision, forming a moat

Suspended design/unsupported process

Designing support structures in suspended (inverted) locations to ensure printing quality is a common practice in 3D printing. Although it helps prevent deformation and collapse of complex parts during the printing process, the support structures may damage design details and increase production costs and post-processing difficulties.

At present, when the angle between the suspended (inverted) shoe mold structure and the horizontal plane is greater than 45 °, the shoe mold structure can achieve self-supporting; If Huashu High tech adopts the "unsupported/low support design" process, it can achieve some shoe mold structures without support at a 25 ° angle.

Size layer thickness combination

Printing processes with different layer thicknesses can be applied within the same work package, and the thickness of the powder layer can be adjusted for different layer thicknesses of work surfaces. Through combination optimization, production efficiency can be improved by 30% -40%.

Intelligent overlap

Adjust the overlap position according to the workload of each layer, so that the working time of the two lasers in a single layer is close, reducing the waiting time between lasers and achieving the maximum utilization rate of multiple lasers.

Shell extraction function

The shoe mold workpiece can be divided into the appearance area and the solid area, and fine parameters and high-speed parameters can be applied respectively to ensure surface quality while improving efficiency.

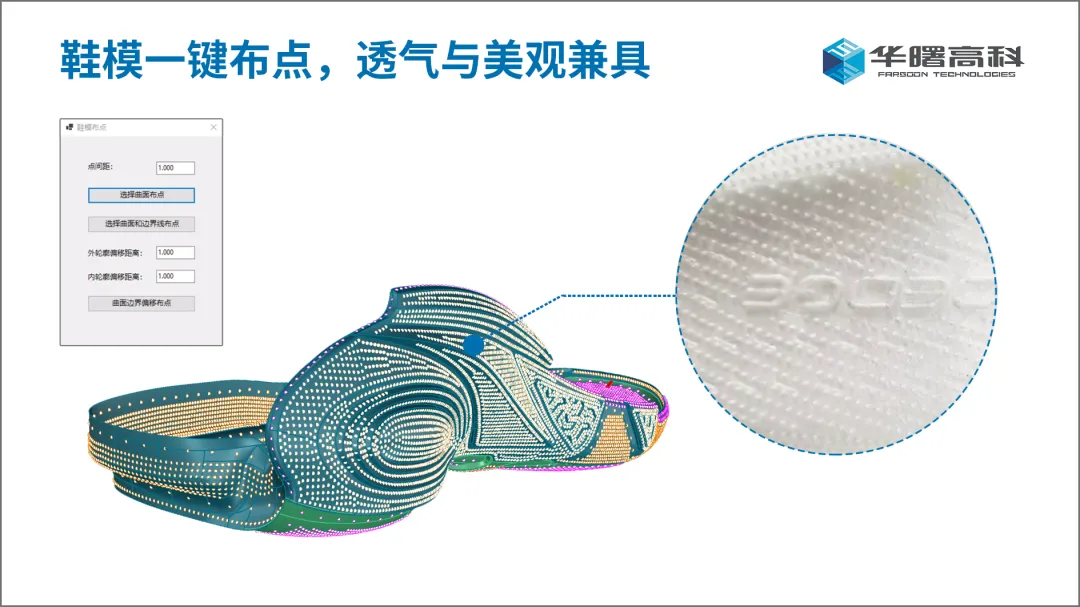

Software shoe model selection and layout function

Huashu High tech released the shoe mold selection and distribution technology specifically designed for shoe mold users in May 2024. Users can automatically calculate reasonable hole placement points based on the characteristics of different surfaces of the shoe mold, and can also customize rules to form personalized or uniform hole distribution effects for different types of surfaces. This not only meets breathability requirements but also generates beautiful patterns, increasing punching efficiency by 25%.

In recent years, Huashu High tech has formed strong alliances with numerous domestic and foreign footwear partners, witnessing the digital transformation of the footwear industry through 3D printing technology. In the future, Huashu High tech will continue to deeply cultivate the footwear market, continuously strengthen technological innovation, and help industrialized users achieve cost reduction, efficiency improvement, innovation and upgrading.

Huashu High tech Shoe Mold Industry Solutions and Diversified Shoe Mold Applications will be showcased at the Formnext+PM South China B01 booth in Shenzhen from August 28th to 30th. Please come and exchange ideas on site!