-

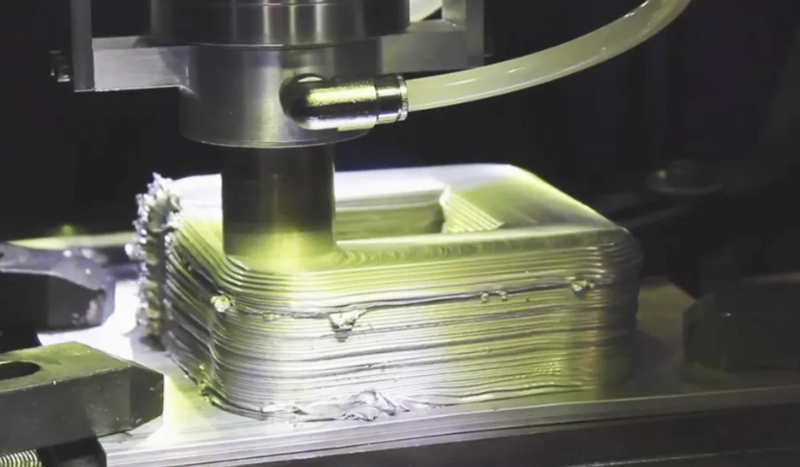

As a typical labor-intensive industry, the traditional shoe mold manufacturing industry is facing multiple challenges such as tedious and complex processes, fragmented labor, strict environmental requirements, and product innovation iterations that better meet market demand. The emergence of new processes and technologies is bound to drive the upgrading and development of the entire industry. 3D printing, as a representative intelligent manufacturing process for the upgrading of footwear manufacturing, will inject unlimited vitality into the research and development of new products and the market....

-

11 types of metal 3D printing technology innovations, affecting the future of manufacturing industryAntarctic Bear Introduction: With the continuous advancement of advanced manufacturing technologies such as 3D printing, the manufacturing industry is ushering in a new transformation. In this wave of change, metal 3D printing innovation is leading the future development of the manufacturing industry with its outstanding innovation and high efficiency. Compared with traditional metal 3D printing technology, these new technologies have brought significant improvements in speed, accuracy, and material selection, redefining our understanding of metal manufacturing....

-

Paul Davies from Sandvik Additive Manufacturing in the UK summarized the current situation and prospects of the MIM industry in Europe and around the world from recent market research and other sources. According to data cited by Data Bridge Market Research, it is expected that the value of the European MIM market will reach approximately 1.6 billion euros by 2027, with a compound annual growth rate of 11.6% from 2021 to 2027. With the recovery of the epidemic, the demand for MIM powder in 2021 has increased by more than 14% compared to 2020. It is said that the demand growth is mainly driven by the automotive industry. The market growth in Europe has increased its share of the world market from an estimated 32% to 48%, surpassing Japan and other regions in Asia (Table 1)....

-

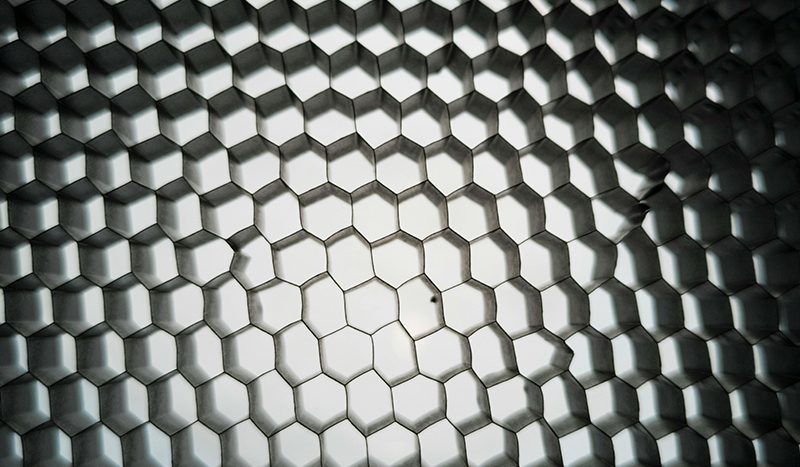

High temperature alloy, also known as heat-resistant alloy or superalloys, refers to an alloy material based on iron, nickel, and cobalt that can resist oxidation, corrosion, and creep at high temperatures above 600 ℃, and can work for a long time under high mechanical stress. Based on the above performance characteristics, high-temperature alloys are currently a cutting-edge industrial material standing at the top of the pyramid. They are not only key materials for hot end components of aviation engines and various high-temperature components of aerospace rocket engines, but also widely used in industrial sectors such as gas turbines, energy, and chemical engineering....