11 types of metal 3D printing technology innovations, affecting the future of manufacturing industry

Antarctic Bear Introduction: With the continuous advancement of advanced manufacturing technologies such as 3D printing, the manufacturing industry is ushering in a new transformation. In this wave of change, metal 3D printing innovation is leading the future development of the manufacturing industry with its outstanding innovation and high efficiency. Compared with traditional metal 3D printing technology, these new technologies have brought significant improvements in speed, accuracy, and material selection, redefining our understanding of metal manufacturing.

At present, traditional metal 3D printing technologies such as powder bed melting (PBF) and directed energy deposition (DED) have been applied in the manufacturing industry, but they also have certain limitations. The new metal 3D printing technology, with its breakthroughs in forming speed, accuracy, and material selection, has established unique technological advantages compared to traditional printing methods, bringing new possibilities to the manufacturing industry. In this article, the Antarctic bear summarizes 11 representative emerging metal 3D printing technologies in recent years and conducts a systematic analysis of their principles and advantages.

(Related reading: Antarctic Bear Inventory: These 20 3D Printing Technologies are Almost Blank in China - Antarctic Bear 3D Printing Network Platform (nanjixiong. com))

1. Seurat Region 3D Printing Technology

The regional 3D printing process developed by Seurat Technologies, a Silicon Valley metal 3D printing startup, uses 2 million laser points to achieve large-scale 3D printing of components. The forming speed of regional 3D printing technology is 1000 times faster than traditional laser 3D printing technology, which can greatly reduce the manufacturing cost of individual parts. At the same time, the components printed by this technology have higher accuracy, with a spot diameter as small as 10 microns, and the processing speed of the area breaks through the limitations of scalability.

Technical principle: Seurat's new technology is based on a new beam processing method to increase the melting amount each time. Its laser system can shoot 2 million laser points at once into a 15 square millimeter square area, with each spot having a diameter of approximately 10 microns, forming one area in one go.

Seurat operates through area printing to achieve complete control of laser intensity. Adjusting the thermal effect can minimize splashing, control microstructure, and reduce residual stress to the greatest extent possible. Seurat area 3D printing technology uses high-speed video, material analysis, and multi physics field modeling to characterize the interaction between laser and powder and solve fundamental physics problems. It can be well applied in the energy field, such as light vehicles, heat exchangers, and new high-performance components.

(Related reading: Metal "area 3D printing" technology with 2 million laser points, speed increased by 1000 times, Seurat raises $41 million in financing - Antarctic Bear 3D Printing Network Platform (nanjixiong. com))

2. XJet Nanoparticle Jet Technology (NPJ)

NPJ 3D printing technology is a new ceramic and metal 3D printing process developed by Israeli company XJet, equipped with a proprietary NPJ printing device that can accurately print various ceramic and metal materials. This additive manufacturing process does not use metal powder raw materials, but uses "ink" filled with nano metal particles to manufacture 3D printed parts.

Technical principle: Crush large molecular metal particles into nanoscale metal particles, and mix them with special adhesive ink to form metal ink. Metal ink is precisely deposited onto the construction platform through the specially designed array nozzle of the NPJ printer, and the liquid evaporates, leaving behind a solidified molten metal layer. Metal ink is sprayed layer by layer to complete the construction, with a layer thickness of less than 2 microns. The formed parts have high precision and excellent surface smoothness.

The advantage of NPJ technology is that it can use ordinary inkjet print heads as tools, and can melt and remove support structures through specialized techniques without the need for any external force. Unlike traditional metal 3D printing processes such as selective laser sintering (SLS), NPJ can significantly reduce raw material waste, lower costs, and give designers greater design freedom. Because it is removed by melting, theoretically it can be added infinitely.

(Related reading: Nanoparticle jetting NPJ metal and ceramic 3D printing technology, XJet's Carmel 1400 (M, C) is here - Antarctic Bear 3D Printing Network - Platform (nanjixiong. com))

3. Electrochemical deposition metal 3D printing technology

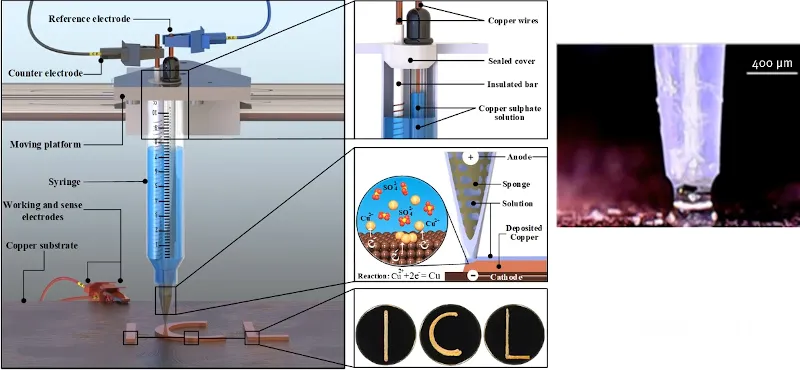

Electrochemical deposition metal 3D printing technology is developed by Fabric8Labs, a startup based in San Diego. This process does not use powder or heat treatment techniques, but is based on the principle of electrochemical deposition and operates at room temperature with greatly reduced power requirements. The printing material is a water-based solution made of low-cost metal salts, combined with ordinary industrial raw materials and energy-saving processes, which can greatly reduce the equipment and printing costs of 3D printers and achieve significant changes.

Technical principle: The electrochemical metal 3D printing system is based on the extrusion principle, and the print head is a syringe filled with electroplating solution, electroplating on a very small area. The printing speed is relatively slow, and if it is too fast, the performance effect will be greatly reduced. By using print heads with different electrolytes, different metals can be used for printing. For example, the following figure shows an electrochemical metal 3D printed structure made of copper and nickel, which can remove metal instead of depositing it by reversing the current.

Electrochemical metal 3D printing can achieve ultra-high precision forming by rapidly depositing raw materials at the atomic level, resulting in high-resolution, precision parts with controlled microstructure, surface smoothness, and density; Printing parts with zero shrinkage, high hanging, no heat post-treatment, and the ability to print independent components or directly build them onto existing substrates, greatly expanding design space; No expensive metal powder or energy intensive heat treatment is required, just use ordinary metal salts to print at room temperature, unlocking new applications that were previously limited by cost; With fully recyclable metal raw materials and low energy consumption, this process achieves sustainability without affecting design capabilities.

(Related reading: Electrochemical deposition metal 3D printing Fabric8Labs raises $19 million, led by Intel, with the potential for large-scale production applications - Antarctic Bear 3D Printing Network - Platform (nanjixiong. com))

In addition, Exaddon, a Swiss company specializing in ultrafine, micro, and nano level metal 3D printing, has developed another electrochemical deposition technology called CERES, which can be used for 3D printing microfabrication of metals at the micrometer level (μ AM). The technical principle is to immerse a small 3D printing nozzle called ionotip into a suspended electrolyte. Accurately adjusting the air pressure will propel the liquid containing metal ions into the microchannels inside the ion head. The liquid flow rate is very small - as low as flying per second. At the end of the microchannel, a liquid containing ions is released onto the 3D printing surface. Then electrodeposit the dissolved metal ions into solid metal atoms. These metal atoms grow together to form voxels in small parts. Optical force feedback records the 3D printing completion status of each voxel until all voxels are printed and a complete object is constructed.

(Related reading: Nanometal 3D printing of parts 100 times smaller than hair, Swiss exaddon electrochemical deposition technology achieves ultra-high resolution - Antarctic Bear 3D Printing Network Platform (nanjixiong. com))

4. High speed cold spray metal 3D printing technology

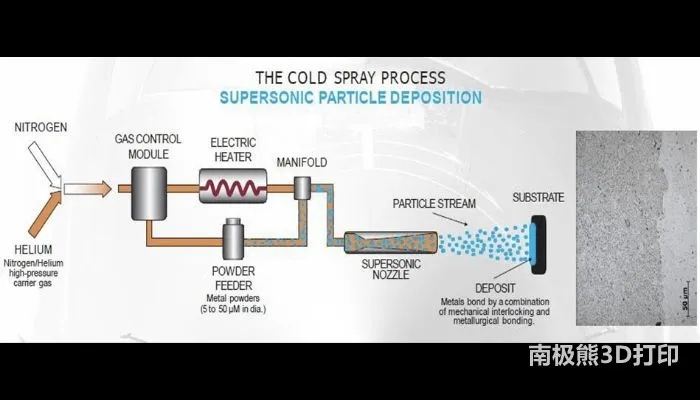

Cold spray metal 3D printing is an emerging solid-state additive manufacturing process in recent years, which can form metal coatings on workpieces or be used to form entire parts. This technology was developed in the 1980s by researchers at the Institute of Theoretical and Applied Mechanics of the Siberian Branch of the Russian Academy of Sciences, who realized that solid particles could be deposited using airflow at room temperature. This technology has been widely applied in military, defense, and maritime fields in recent years.

Technical principle: Using pressurized gas (such as air, nitrogen, or helium) as the propulsion gas at high temperatures, metal or even ceramic powder raw materials are accelerated to speeds ranging from 300 to 1200 m/s through a specially designed converging expanding nozzle. When these high-speed powder particles collide with the surface of the substrate (usually metal), they undergo severe plastic deformation and then deposit to form thin coatings or bulk deposits. The formation of cold spray deposits mainly relies on the kinetic energy of particles before impact rather than thermal energy, so the cold spray particles remain solid throughout the entire deposition process. The solidification of particles is mainly achieved through mechanical interlocking and local metallurgical bonding at the interface between particles. The spraying process is completed by combining a nozzle and a robotic arm, both of which can be moved.

Australian companies Titomic and SPEE3D, Chinese company Chaozhuo Aerospace Science and Technology, and German company Linde are typical application manufacturers and technology developers of cold spray metal 3D printing technology. Among them, SPEE3D's patented "supersonic particle deposition" technology has been applied to the defense fields of Australia, the United States, the United Kingdom, and Japan. This technology is 1000 times faster than traditional metal 3D printing techniques such as adhesive jetting and DMLS, provided by WarpSPEE3D 3D metal printers.

(Related reading: 8000 words of dry goods! Development status of cold spray metal 3D printing technology - Antarctic Bear 3D Printing Network Platform (nanjixiong. com))

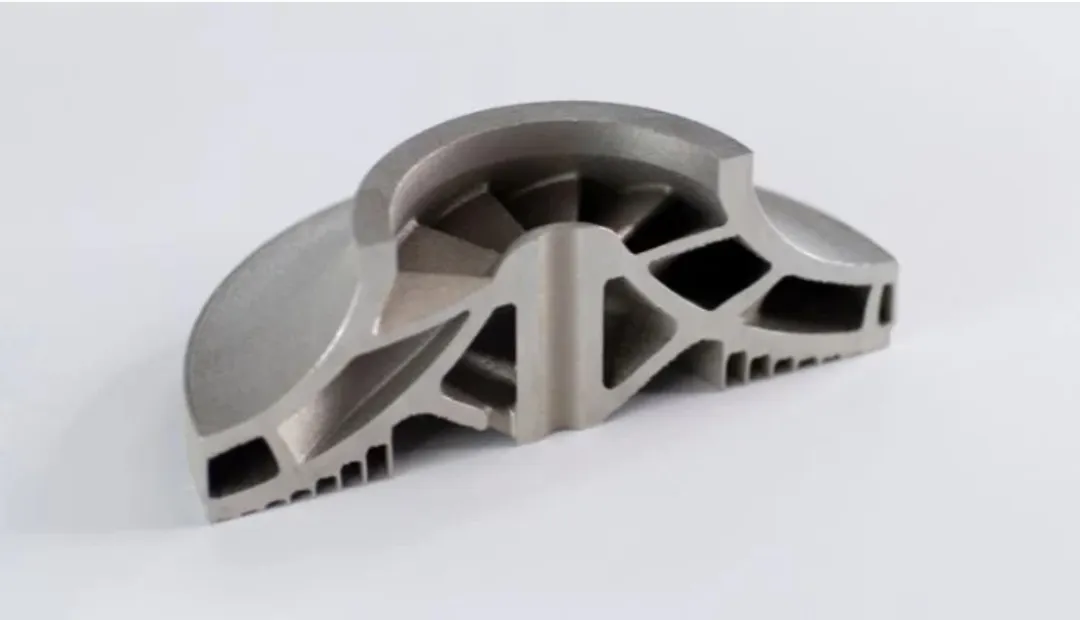

5. Unsupported metal 3D printing process

The addition and removal of supports have always been a major challenge in the process of metal additive manufacturing. Taking direct metal laser sintering (DMLS) as an example, a support structure needs to be pre-set for the model before printing to avoid deformation caused by thermal stress and to conduct heat out of the melt pool. If there is no support, it is difficult to print suspension structures below a certain tilt angle (usually around 45 °), which often limits the choices of metal 3D printing system users and poses great challenges for many equipment OEMs and additive manufacturing software companies. These supporting structures need to be dismantled and discarded after the completion of component construction, which also brings problems such as material waste and increased post-processing costs. So, developing metal 3D printing processes with little or no support is a challenge that metal 3D printing companies have been committed to overcoming.

316L unsupported impeller printed by EOS

In recent years, several metal additive manufacturers have released unsupported/low support metal 3D printing technologies, some have released process software, and some have even released equipment. For example:

In 2018, Velo3D from California, USA, unveiled its sapphire DMLS system for the first time at the International Manufacturing Technology Show (IMTS), becoming a pioneer in exploring unsupported 3D printing. The key to the sapphire system is Velo3D's intelligent fusion technology, which can simulate and predict part deformation, eliminating the need for supporting structures.

In May 2021, German metal 3D printing manufacturer SLM Solutions, as a global leader in multi laser metal printing, showcased a batch of high-quality application samples and the latest FreeFloat unsupported technology at TCT Asia.

In November 2022, German EOS experts proposed an optimized solution for unsupported metal 3D printing, which can achieve unsupported printing of closed impellers; In April 2023, EOS officially announced the launch of Smart Fusion software that can be laser adjusted, eliminating the need for a large number of support structures, minimizing material usage, and reducing post-processing requirements.

In May 2023, the Antarctic bear visited Yijia 3D, and the company has begun to apply unsupported metal 3D printing technology to some equipment; At the September Asian TCT, relevant parts were showcased, and mature process parameters were perfected and debugged. Some customers are already using them.

In June 2023, PolyGram announced that it had developed a technology solution for unsupported metal 3D printing and demonstrated various types of parts printed using unsupported technology.

In September 2023, Huashu High tech showcased its heavyweight new products, ultra large size solutions, and low support technology at 2023TCT Asia.

In September 2023, Hanbang Technology demonstrated at TCT the ability to achieve unsupported forming with 15-25 ° tilt characteristics, greatly reducing the dependence of parts on support structures.

In September 2023, Beifeng Technology demonstrated at TCT that it has achieved unsupported printing at angles of 15 ° and above, with the functionality integrated into Beifeng's self-developed software.

In September 2023, Germany's TRUMPF Group improved its 3D printing software TruTops Print to print metal parts with hanging angles as low as 15 degrees almost without the need for supporting structures.

In February 2024, the core research team of Jinshi 3D, Professor Yang Yongqiang and Professor Wang Di from South China University of Technology, jointly published a special invited paper titled "Research on the Method and Process of Laser Selective Melting Forming Low Angle Unsupported Structures" in the journal "China Laser". The paper explored the forming mechanism, sample surface quality, and applicability of the forming method of unsupported metal printing, and verified the printing using actual industrial parts.

In March 2024, Leiming Laser, with rich industry experience, systematically explored multiple key links of laser selective melting technology, further optimized printing strategies, developed new process technology solutions, and achieved unsupported forming of small angle (5 °~35 °) parts.

Related reading: Technology has been breached, unsupported metal 3D printing will blow the Chinese wind - Antarctic Bear 3D Printing Network Platform (nanjixiong. com)

6. Intelligent layered metal 3D printing

3DEO in the United States is the pioneer of Intelligent Layering metal 3D printing technology. The company claims that using its intelligent layering technology, it can mass produce parts while reducing costs and meeting industry standards for metal injection molding. In addition, it can produce metal components with excellent surface quality, low cost structure, and fine functionality for customers in the medical, defense, and aerospace markets.

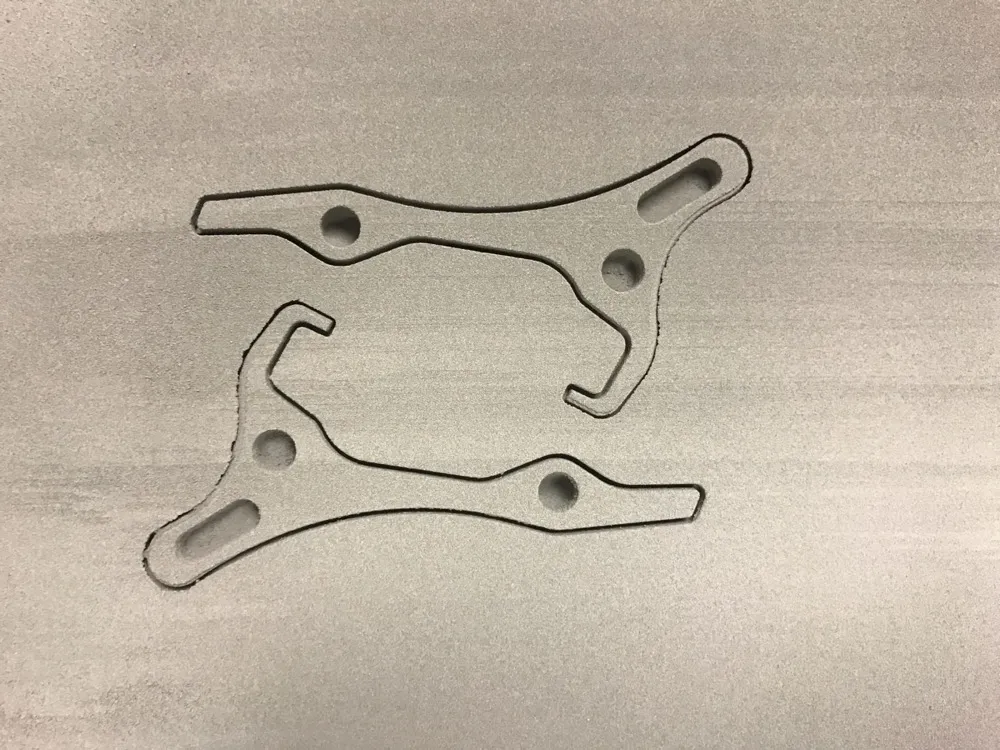

Technical principle: Using a dedicated nozzle to spray adhesive solution on a metal powder bed, and then using a CNC milling machine to process according to the contour and internal characteristics of the part. The printed green body is sintered in a high-temperature furnace to achieve the final solid density.

Metal parts processed by CNC during intelligent layering process

3DEO intelligent layering technology can support a large amount of metal powders on the market, with a cost five to ten times lower than the spherical powders used in PBF powder sintering processes. This technology simultaneously solves the high cost and low yield challenges of metal additive manufacturing. Meanwhile, the consistency is very high. Due to the use of dense fine powder, the parts obtained by 3DEO sintering have a very high surface finish at around 100 Ra.

(Related reading: With an annual output of millions of metal 3D printed parts, competing head-on with machining and MIM, 3DEO's low-cost mass manufacturing technology has arrived - Nanjixiong 3D Printing Network Platform (nanjixiong. com))

7. Additive Stir Friction Deposition Technology (AFSD)

MELD Manufacturing Company in the United States is the developer of the additive stir friction deposition (AFSD) process, which is considered a game changer in the field of 3D printing due to its solid-state properties. This unique feature sets it apart from traditional high-energy beam fusion processes. Unlike additive manufacturing methods that involve melting metals, MELD's solid-state printing can be printed using alloys such as 7075 and 2219 aluminum, which is crucial for industries such as aerospace that prioritize lightweight components. In addition, MELD can produce widely used aluminum alloy 6061 parts without the need for special powders or alloys. MELD technology has a wide range of application prospects, including additive manufacturing, coating applications, component maintenance, metal connections, customized metal alloys, and metal based composite material blanks and parts manufacturing.

Technical principle: Using a hollow rotating shaft and nested feeding rod inside, the solid material is extruded and fed outward in the axial direction. When the feeding rod comes into contact with the substrate below, it begins to apply and adhere to the substrate through friction, undergoing plastic deformation but never melting. The rapidly rotating tool has the function of heating the material, giving it sufficient plasticity to undergo such severe plastic deformation. Once the first layer is applied, the feeding rod will be simply lifted and pushed back to print more layers until the final 3D component is completed.

Additive stirring friction deposition technology. The photo is from MELD Manufacturing Company.

As a solid-state process, MELD can produce high-quality materials and parts with lower residual stress and full density, while consuming much less energy than traditional processes. Due to the solid-state printing process of MELDing, it also produces materials that are not easily affected by porosity, thermal cracking, or other common issues based on melting technology; A single step process that does not require time-consuming post-processing, such as hot isostatic pressing (HIP) or sintering, can improve the quality of deposited materials. In addition, MELD printers eliminate the hazards associated with metal powder by using standard metal bars and can be used for outdoor printing. This enables MELD machines to economically produce very large parts, demonstrating enormous application prospects in the field of military maintenance. The US Army has fully utilized the potential of MELD's large-scale printing capability, collaborating with multiple research institutions to carry out large-scale seamless hull projects and printing super large aluminum cylinders with a diameter of up to 3.05m.

(Related reading: MELD Manufacturing Company collaborates with universities to advance new technology research on 3D printing technology using friction stir deposition, which is ten times faster than SLM - Antarctic Bear 3D Printing Network Platform (nanjixiong. com))

8. Electromagnetic Liquid Metal 3D Printing Technology

The electromagnetic liquid metal 3D printing technology originated from Vader Systems, which has now been acquired by Xerox. They combined Magneto Hydro Dynamics (MHD) and Liquid Metal Jet Printing (LMJP) into a unique technology called Magnet-o-Jet. This is a unique and original technology that utilizes electromagnetic force to disperse molten metal liquid.

Technical principle: Use metal wire as raw material instead of powder, and print liquid metal droplets through magnetic control. Heating and melting metal wire into liquid state in a ceramic crucible → dispersing liquid metal into droplets using electromagnetic pulses → spraying them out through a ceramic nozzle. The magnetic field causes metal droplets to move precisely to specific positions and then stack to form. The produced parts have high precision and isotropic material properties.

△ Metal droplet accumulation process

The existing metal welding wires in the market have relatively low costs and are widely used. Printing these materials through unique technology can become a universal foundational technique. If multiple liquid droplet metal printing heads are arranged in an array, or if one head can spray different types of materials, the application prospects will be even broader. At present, they support several types of materials including steel (316, 718) and metals such as aluminum. Vader droplet metal 3D printing technology avoids the complex process of degreasing and sintering, and greatly reduces costs, so Xerox has decided to continue increasing investment. Due to Xerox being one of the global leaders in jet printing technology, adept at accurately printing materials into precise positions, it is a very suitable promoter for this technology.

(Related reading: VaderSystems launches three new Magnet-oJet liquid metal AM systems - Antarctic Bear 3D Printing Network - Platform (nanjixiong. com))

9. Wire Melting Metal Deposition (MMD) Technology

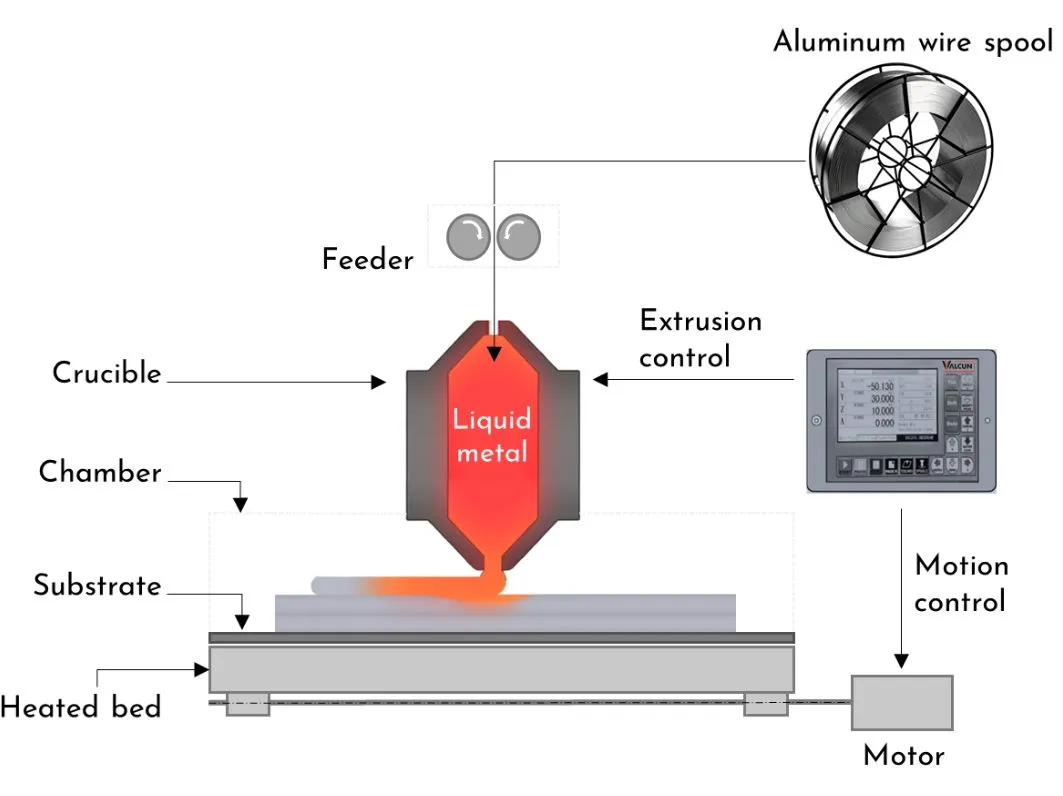

Molten Metal Deposition (MMD) technology is a new metal 3D printing technology independently developed by Belgian metal 3D printing startup ValCUN. This technology uses a new energy source instead of a laser, which can achieve lower cost and more efficient printing. MMD technology does not have specific requirements for the form of printing materials, and can be compatible with wires, particles, and even recycled materials, making it suitable for mass production.

Technical principle: The metal wire raw material is melted and directly extruded into the final component. During the deposition of molten metal, the long wire is fed into the heating chamber by the feeder. Metal melts in this heating chamber. There is a nozzle at the bottom of the chamber through which liquid metal is extruded. The extruded metal fuses with the previous layer (or substrate) to form a component. At the end of the process, the component can be easily separated from the substrate.

Compared with other metal 3D printing technologies, MMD can be quickly upgraded and is easy to use. The raw material used is commercially available welding wire, which does not require expensive metal powder and related costs or proprietary formulas, and can reduce costs; The MMD process only requires direct melting and deposition of the metal, without the involvement of adhesives, so there is no need for degreasing or sintering post-treatment; MMD technology, due to controlled solidification, can print unsupported components with up to 75 ° overhangs and 25mm bridges; Printing with low thermal gradient ensures that residual stress, deformation, and cracking issues of the components are negligible. MMD technology is currently mainly developed for aluminum materials, as most additive manufacturing technologies are not the most suitable for producing aluminum.

(Related reading: ValCUN Belgium: Wire Melting Metal Deposition (MMD) technology solves the problem of aluminum printing!)- Antarctic Bear 3D Printing Network - Platform (nanjixiong. com)

10. 3D Nanometal Printing Technology

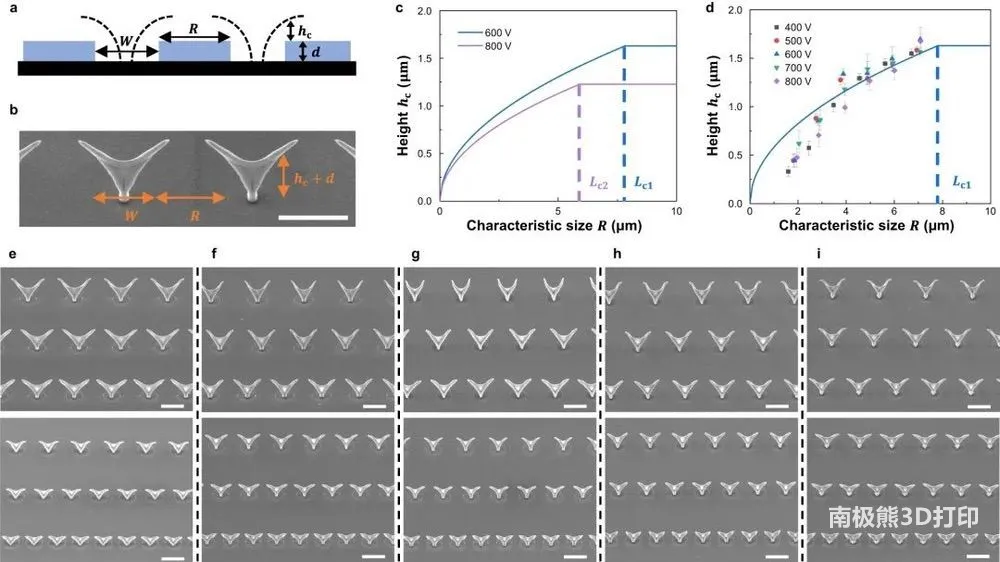

Researchers from Feng Jicheng's research group at the School of Material Science and Technology, ShanghaiTech University, and Busan National University in South Korea have proposed a new type of 3D nanoprinter that can be used to print structures ranging from single metals to multiple materials, including various periodic arrays and complex nanostructures.

Technical principle: Printing is carried out under environmental conditions, synthesizing aerosol nanoparticles through gas-phase methods, some of which are charged, and mapping the electric field to 3D geometric shapes with the help of patterned photoresist (PR). By controlling the applied electric field and adjusting the flow field, the size of nanoparticles (NPs) is precisely selected as the building block for in-situ printing. The geometric mean diameter of nanoparticles is 3-5 nm, with a geometric standard deviation of 1.2-1.4.

Draw local fields through 3D printing of nanostructures.

3D nanometal printing technology can print metal wires as narrow as 14nm, as well as periodic arrays of complex 3D nanostructures of various materials, with high uniformity, efficiency, and purity. The electric field and flow field are coupled so that the size of NPs can be selected based on the difference in their electric mobility, eliminating the influence of material properties.

(Related reading: Feng Jicheng's research group at ShanghaiTech: A new type of metal 3D nanoprinting! Expected to be used in chip manufacturing - Antarctic Bear 3D Printing Network Platform (nanjixiong. com))

11. New directional energy deposition technology

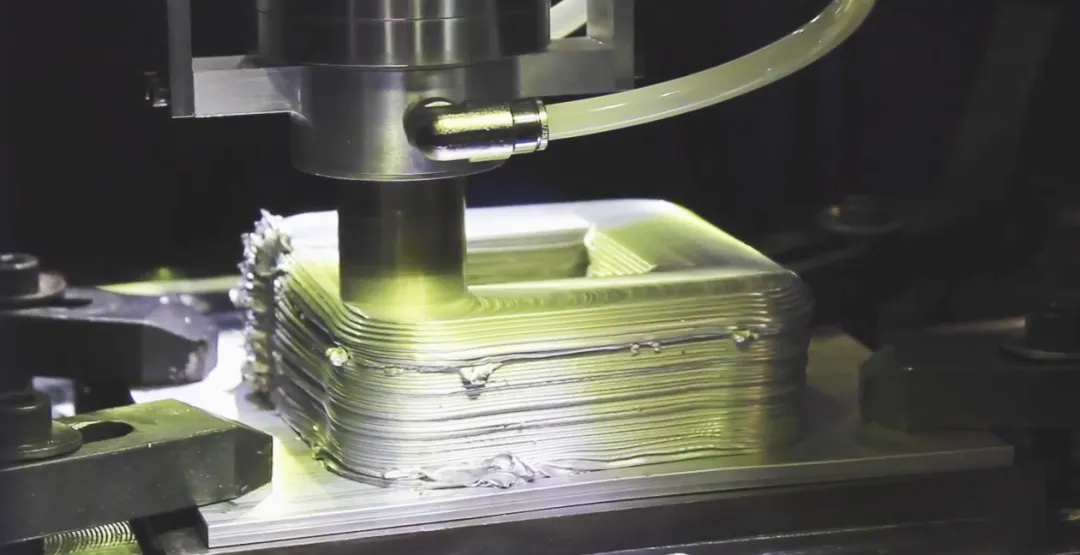

Directed energy deposition (DED) technology is often used to manufacture large metal components due to its high deposition rate. However, the high energy input of traditional arc additive technology often leads to issues of high remelting, reheating, and grain coarsening at relatively high deposition rates, thereby reducing the mechanical properties of the parts.

Researchers from Cranfield University in the UK have proposed a novel arc additive DED process that combines gas metal arc (GMA) technology with external cold wire, known as cold wire gas metal arc (CW-GMA), to achieve high deposition rates and low material remelting. By adding cold wire, the remelting phenomenon is significantly reduced, the strength of the workpiece is enhanced, and the anisotropy is reduced.

Schematic of △ Line Arc Additive Manufacturing (WAAM) Technology

Domestic institutions such as Nanjing University of Technology have proposed a new integrated additive manufacturing technology - oscillating laser melting deposition. The technical principle is to apply external forces to the laser melt pool, causing more intense agitation and flow changes in the melt pool, thereby inducing grain refinement and columnar equiaxed transformation. The laser oscillation paths applied include linear, circular, 8-shaped, and infinite shapes.

Related Reading:

The new arc additive manufacturing technology has achieved a deposition rate of over 10kg/h, reduced grain size, and improved mechanical properties - Nanjixiong 3D Printing Network Platform (nanjixiong. com);

Joint Top Issue of Six Chinese and Foreign Universities: New Laser Additive Manufacturing Technology for Titanium Alloy Grain Refinement and Synchronous Reinforcement Toughening - Nanjixiong 3D Printing Network Platform (nanjixiong. com)

END

The Antarctic bear believes that the continuous emergence and innovation of new metal 3D printing technologies have brought unprecedented opportunities and challenges to the manufacturing industry. These technologies not only change traditional manufacturing methods, but also redefine product design and production processes. By improving production efficiency, precision, and material selection range, the new metal 3D printing technology injects new vitality and momentum into the future development of the manufacturing industry, and is truly a new quality productivity.

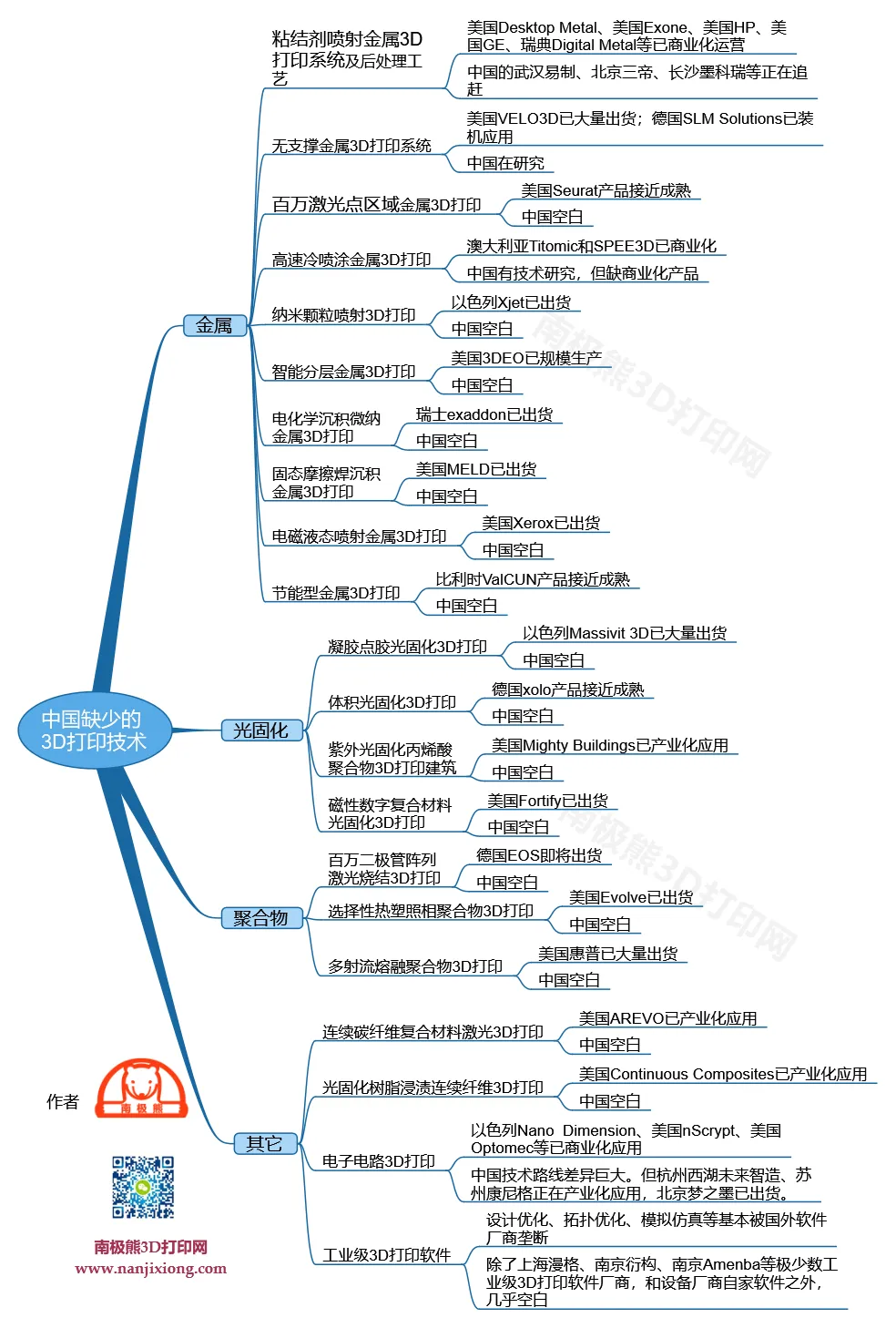

With the continuous evolution of technology and the expansion of applications, we are confident that metal 3D printing technology is playing an increasingly important role in aerospace, medical, automotive and other fields, helping the manufacturing industry move towards intelligence, efficiency and sustainable development. However, it should also be noted that China's exploration and research in the field of new metal 3D printing is lacking, and there is a significant gap or even a complete blank compared to international cutting-edge technologies. In the future, we still need to face up to the gap, fill in the gaps, continuously innovate and develop new metal 3D printing technologies, and further promote China's manufacturing industry to move towards a more intelligent and efficient direction.